Lumber Terminology 101: Understanding Wood Talk Before Your Custom Build

Lumber Terminology 101: Talk Wood Like a Pro

When you’re planning a custom table or furniture piece and begin working with a woodworker (hopefully me), you’ll probably hear some familiar and unfamiliar terms like “ hardwood”, “quarter-sawn,” “board foot,” or “4/4 thick” It can sound like a different language, be pretty intimidating and overwhelming if this is your first time getting a custom piece of furniture. I want this guide to help de mystify these terms get you familiar and to feel confident when you are conversing with your craftsperson (again hopefully me). You will be able to communicate in the same language to design and craft your dream piece of furniture.

1. Types of Wood

Hardwood vs. Softwood

Hardwoods: come from deciduous trees (leafy trees) such as walnut, maple, and oak. They’re dense, durable, and ideal for furniture.

Softwoods: come from conifers (needle trees) like pine, spruce or fir. They’re lighter and often used in the construction industry as framing, shelving, or decorative elements like tongue and groove paneling or moldings.

Domestic vs. Exotic Woods

Domestic woods are trees native to your local region. In North America, where I am poplar, maple, cherry, ash, walnut, and oak are among the most common examples. These species are sustainably sourced, easy to work with, and typically a more affordable option than imported exotics. They offer a wide range of natural colors and grain styles, making them versatile for almost any design.

Exotic woods are imported from other countries and are not native to the area. They are often prized for their rich color and striking grain patterns. Many exotic species have a higher natural oil content, making them excellent choices for outdoor furniture and decking. Because of their year-round growing conditions, exotic trees can also produce exceptionally wide boards and slabs.

Both domestic and exotic woods have their place in fine furniture and beyond. A skilled craftsperson can help guide you toward the best species for your design, balancing beauty, performance, and purpose. Lumber selection is one of many factors that go into pricing a custom dining table, find our the other factors in my post how much does a dining table cost?

2. Lumber Cuts and Grain Orientation

The way a log is cut at the mill determines both appearance and stability.

Flat-sawn (plain-sawn): flat sawn wood is made when the log is sliced straight across from top to bottom like cutting bread. this way shows the big curved lines called cathedrals on the surface of the board. it’s the most common way to cut wood because it gives wide boards and wastes less of the tree, but the grain can move more with changes in humidity.

Quarter-sawn: quarter sawn wood is made when the log is first cut into quarters and then sliced from each section. this makes the grain lines stand up straighter, between about 60 and 90 degrees on the end of the board. it’s more stable than flat sawn wood and can show long straight lines or shiny flecks called “ray fleck” on certain species of wood. Most common is quarter sawn white oak. This will also produce more waste compared to flat sawn cutting.

Rift-sawn: is made when a log is cut so the tree’s growth rings meet the surface of the board at a special angle, usually between 30 and 60 degrees, most often around 45 degrees.

Think of it like cutting a tree at a slant instead of straight across or flat. This way, the lines in the wood (the grain) look super straight and even. Because it takes more careful cutting, rift-sawn boards cost more, but they’re really strong and don’t twist or bend as much. These are great for chair legs since the grain is the same on all 4 sides of the board.

3. Lumber Thickness Explained (4/4, 6/4, 8/4)

Hardwood thickness is measured in quarters of an inch while still in its rough-sawn state. Each “quarter” represents ¼ inch. the most common thicknesses you will hear about are 4/4. 6/4, and 8/4

After surfacing, the final thickness is slightly less. For example, 4/4 rough lumber typically finishes around ¾”. Some mills also carry 5/4, 10/4, or 16/4 stock for specialty or extra-thick builds.

4. Lumber Dimensions and Milling Terms

Rough-Cut: Rough lumber is the raw form of wood that comes straight off the saw at the mill, with a textured rough surface with no flat faces or 90 degree edge. This lumber is then either air dried or kiln dried to help stabilize it and get it ready for sale.

Surfaced Lumber: Surfaced lumber or dressed lumber is wood that has been through some form of milling process. Many custom furniture makers including myself surface and mill our own lumber from a rough state but you can buy pre milled lumber at your local wood store or big box store it will typically be labeled as S2S (surfaced 2 sides) meaning 1 face has been jointed or planed and 1 edge has been ripped or jointed straight. You can also get S4S (surfaced 4 sides) and this is wood that has been milled on both faces and both edges making it ready to work with right from the store.

Board Foot (BF):

Lumber is sold by volume. One board foot equals 1 inch thick × 12 inches wide × 12 inches long.

Example: a board that’s 1” thick, 6” wide, and 8’ long = 4 board feet.

Linear foot (LF): A linear foot measures the length of a board, regardless of its width or thickness.

It’s a simple way to price materials that come in consistent shapes or profiles, like moldings, trim, baseboards, or edge banding. You can purchase wood this way but the wood will usually all be cut to a consistent width.

To calculate it, you just measure how long the piece is in feet.

For example:

A 1” x 3” moulding that’s 8 feet long equals 8 linear feet.

If the price is $2 per linear foot, then 8 × $2 = $16 total.

Linear footage doesn’t factor in the width or thickness of the material, only its length, which makes it ideal for products that are all the same size and shape.

5. Grain Types and Faces

Each board has three distinct faces:

Face Grain: The broad, flat surface, where the natural figure and grain pattern are most visible. usually the widest part of the board

Edge Grain: The long, narrow edge, perpendicular to the face grain

End Grain: The cross-section of the tree, extremely durable and used in high-end cutting boards

6. Wood Figure

Figure refers to the natural grain patterns that make each board unique. Some boards show very little figure, while others are highly figured with striking movement and depth. It’s often impossible to see from the outside of the tree and may only reveal itself once the log is cut into boards.

“Figure” is a broad term that covers many different grain effects, and it’s often how we describe wood that stands out from the ordinary. No one fully knows what causes figure to form, which makes the boards that display it truly one of a kind in every way.

A few common types of figure are shown below,

Curl / Flame /fiddleback/ Tiger Stripe: Fiddleback describes a tight, wavy grain pattern that runs across the board in even, parallel lines. It gets its name from its frequent use on the backs of violins and other string instruments, where the pattern catches light beautifully and gives the wood a sense of movement. When finished properly, the rippling grain seems to shift and flow as you move your eyes across the surface, creating a truly mesmerizing effect.

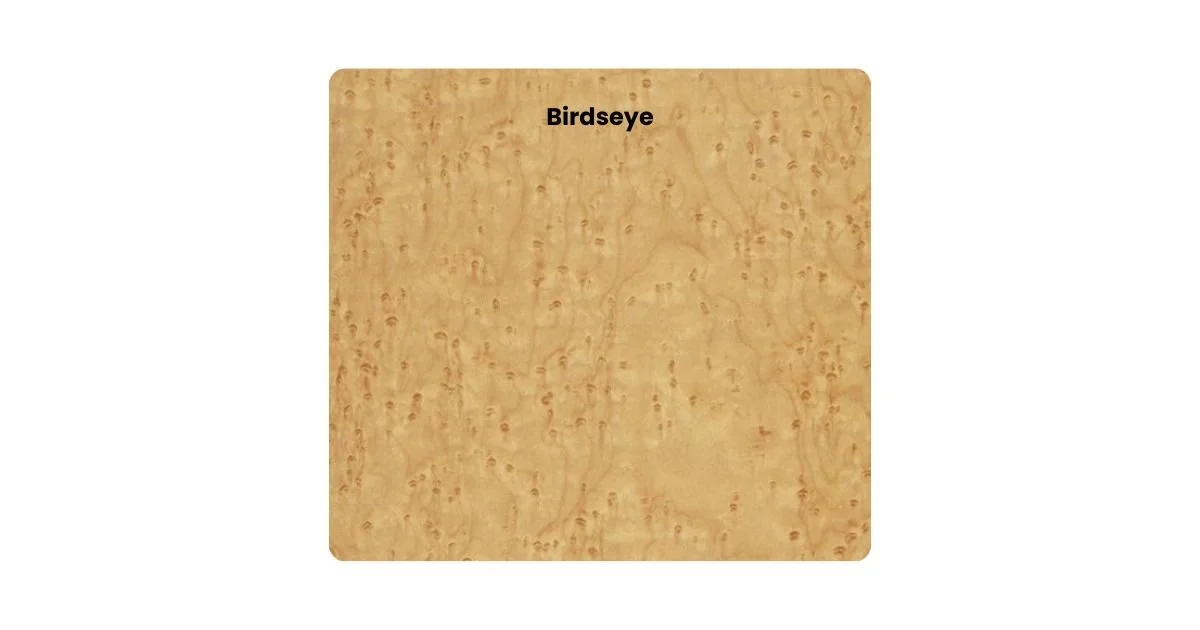

Bird’s Eye: Birdseye is a rare and captivating wood figure made up of hundreds of tiny, swirling dots that resemble small eyes scattered through the grain. It forms when a tree experiences stress and attempts to grow new shoots but cannot sustain them, leaving behind small knots that create the distinctive “eye” pattern. No one knows for certain what causes this phenomenon, but that mystery only adds to its charm.

Quilted: Quilted figure has a soft, wavy pattern that looks almost like ripples on water or folds in fabric, that’s where it gets its name. The effect happens when the grain in the tree grows in irregular, undulating layers instead of straight lines.

You’ll most often see quilting in maple, mahogany, sapele, and ash, though it can appear in other hardwoods too. When finished, the surface shimmers as light moves across it, creating a three-dimensional look that feels alive, also known as chatoyance (pronounced sha-toy-ance)

Quilted figure is highly prized for its depth and movement, making it a popular choice for fine furniture, tabletops, musical instruments, and decorative panels.

Spalting: Spalting happens when certain fungi grow inside wood and create beautiful, natural patterns. Instead of ruining the wood, the fungi leave behind dark lines, colour streaks, or pale areas that highlight the grain and give each piece a one-of-a-kind look.

It’s most common in maple, birch, beech, and boxelder, though it can appear in many hardwoods. Spalted maple is the most recognizable, with black lines that look almost like ink drawn through the wood.

Burl: A swirl or cluster of twisted grain from a growth deformity, producing one-of-a-kind visual texture. Burls are growths on trees and can be common on some tree species like poplars and maples and can be very rare on others like cocobolo. They make for some truly one of a kind pieces with stunning grain patterns and most often are found in veneered sheets or pre made panels.

Crotch Figure: Crotch figure forms where a tree trunk splits into branches, causing the grain to twist and overlap into a dramatic flame or feather pattern. It’s most common in walnut, mahogany, and cherry, prized for its rich depth and natural movement.

7. Wood Movement and Deformation

Wood expands and contracts with changes in humidity. Even kiln-dried lumber moves slightly with the seasons. proper joinery and milling practices will help aid in the reduction of movement but will not eliminate it as wood is a natural material that will change with the seasons.

Common deformations prior to milling

Cup: Curves across the board’s width. will look like a smiley or frowny face when looking at the end grain, In tables or large panels, stiffeners of wood or metal ae used to help keep the wood flat but allow for the wood to still move freely.

Bow: Curves along its length. Will look like a rainbow or U shaped when looking at the side grain

Twist: Corners rise unevenly.

Crook or crown: A side bend along one edge. The wood will bend side to side when looking down the length of the board viewed from the end grain

Check: Small surface crack from drying. can be located anywhere on the surface or ends of boards, usually formed from improper drying

Split: A deeper crack through the board. can be from stresses in the wood be releases or from improper drying

Wane: The presence of bark or missing wood along an edge.

Knots/knot holes: Knots are areas where branches once grew, leaving circular patterns in the grain that add character but can also create weak points. When a branch dies or breaks off, the tree grows over it, and the old knot may decay, loosen, or eventually fall out of the wood.

8. Grading and Quality

FAS (First and Seconds):

The standard top-grade hardwood, offering at least 83% clear usable area. Boards must be at least 6" wide and 8' long.

Some suppliers label higher than FAS material as Superior Grade, Prime, or Extra Clear, though these aren’t official industry terms. FAS is good for 95% of projects but certain situations require to go above and beyond the regular standard to achieve the color or look you are after.

Select and Better:

A lower grade but still excellent for furniture making. Will have a few more knots, pin holes, wane or other defects compared to FAS. A great option if smaller pieces are required since parts can be cut around knots and other defects. Or if you are looking for a more rustic natural looking piece.

Common Grades:

Include No. 1 Common, No. 2 Common, and No. 3 Common, each with increasing knots and shorter clear sections. The lowest-quality boards are often sold to flooring mills or repurposed into firewood or mulch.

Note:

Grading affects appearance, not strength. Higher grades provide larger, defect free sections and more consistent color, which impacts price and yield. Lower grades can still produce beautiful pieces, they just take more careful planning and selection.

9. In-Home Considerations

Solid wood is a living, breathing material even after it has been cut, dried, and finished. It naturally responds to changes in temperature and humidity in your home.

Acclimation:

When your piece first arrives, it will adjust to your home’s environment. Wood absorbs and releases moisture as the seasons change, which can cause slight movement at joints or along seams. This is completely normal. You might notice a joint feel slightly raised or recessed during the first few weeks as the table settles in. Over time, it will find its equilibrium point.

Climate and Humidity:

The ideal indoor humidity for solid wood furniture is between 35% and 55%. Extended exposure to very dry air, especially in winter with heating systems, can cause wood to shrink slightly, while high humidity can make it expand. Using a humidifier or dehumidifier helps maintain a stable environment and prevents unnecessary movement or cracking.

Placement:

Avoid placing solid wood furniture near heat sources, vents, fireplaces, or in direct sunlight. Heat and UV exposure can cause drying, fading, or warping over time. If sunlight is unavoidable on your table it is good practice to spin your table so it receives even sunlight on all parts of it so its natural patina is consistent. Also a good idea to remove place mats center pieces and other décor when not in use to prevent sun spots

Installation:

Wide tabletops and slabs are always attached with specialized hardware that allows for expansion and contraction. They should never be rigidly fixed to a base. This design ensures your table can move naturally with the seasons without damage. All custom solid wood furniture should consider wood movement when choosing joinery and grain direction to prevent unwanted cracking or warping over time.

Long term Care:

Minor movement, hairline shifts, or small surface changes are part of the natural character of real wood. Unlike manufactured materials, solid wood gains depth and personality over time, developing a patina that makes each piece unique to your home.

Proper handling, stable humidity, and mindful placement will keep your furniture beautiful and sturdy for generations.

Closing Thoughts

Understanding basic lumber terminology helps you and I communicate your vision clearly and appreciate the craftsmanship behind your custom piece. Having this knowledge gives you confidence when speaking with a craftsperson about a potential project or confirming the details of your project. Learn more about the styles of dining tables and why a custom tables beat mass produced every time.

I hope you found this guide helpful and learned something new about the materials that go into your furniture. I would love to hear your thoughts or experiences in the comments below as your feedback helps me create more useful resources for future clients. If you are interested in a custom piece please reach out via my contact form here.

Catch you on the next one.

Cheers

Harley Griffin

Chief Sawdust Maker at Stone Mountain Projects

Built to Build Memories.